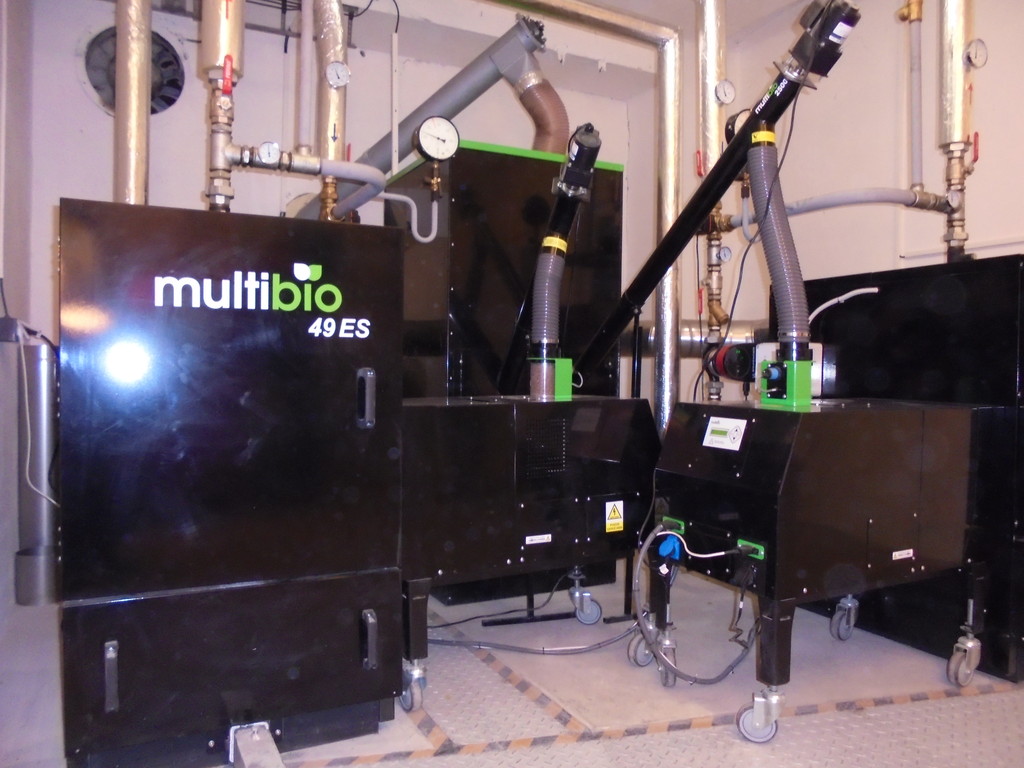

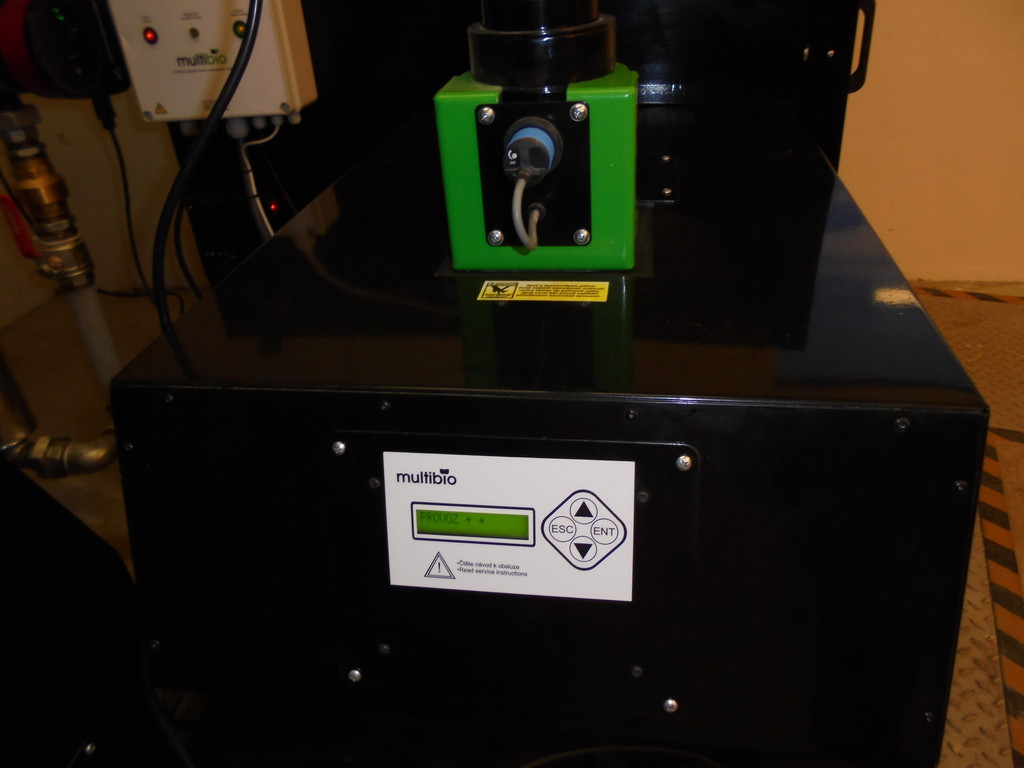

In the reference - boiler room of Navos from Miroslav u Znojmo you can see the automatic solution with Multibio 49 ES boilers for plant pellets. The fuel supply is automatic, with an auger from the outside force to the daily hopper located in the boiler room. The hopper is common to both boilers. From the hopper, the fuel is transported by Multibio screw conveyors to the burners. Boiler refueling is drained, as seen in the photograph, below the level of the screw conveyor floor, which removes ashes away from the boiler room into the ash container. The boilers supply the heating office three-storey building, store with store and also workshops where the servicing of agricultural machinery is performed. Boiler ignition, power operation and modulation are fully automatic. The boilers do not have a damping mode and do not bother with the smoke of the surroundings. Navos is also a producer of vegetable pellets with the potential to produce 3000 t of pellets per year. The Navos Multibio boiler replaced two gas boilers for propane butane. The saving on fuel consumption will be about 200 000, - CZK per year. For boilers it is possible to connect electronics to LAN / GSM. The precise installation and design of the boiler room is a work of Martin Dudík from Plumlov near Prostějov.